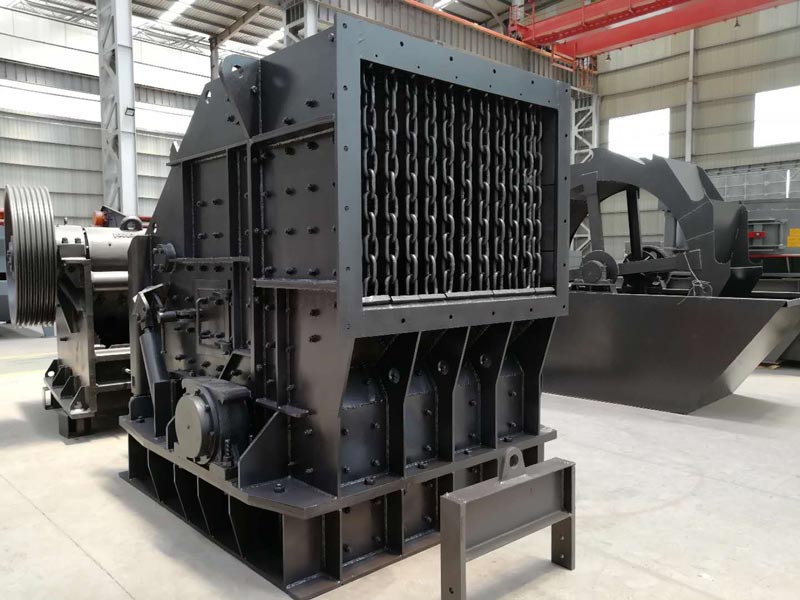

Impact crushers are one of many crushing machine types, including cone crushers, hammer mills, and jaw crushers, that is made for processing different types of raw materials, such as asphalt, limestone, basalt, and many other types, to reduce their size.

Used for various applications, which include aggregate crushing, concrete crushing, aggregate crushing, etc., impactors are unique to crushers since it breaks stones and rocks apart by striking a material rapidly rather than using a pressurized force. Keep reading to get more information about the crusher impactor.

Working principle of impact crusher

The impactor crusher has a mechanical structure defined by a rotor, which is the main instrument that breaks the materials apart. This router is installed among mounted aprons, anvils, or plates, set inside a robust and heavy housing. The anvils or aprons endure the impact caused by the materials that are being processed which breaks the material even further apart.

VSI crusher and the HSI crusher

The impact crushers come in two styles which include the VSI (vertical shaft impactors) and the HSI (horizontal shaft impactors). The feature that distinguishes these two types is how the rotor is physically orientated in the impactor.

In a horizontal shaft impactor, the rotor is horizontally oriented and uses hammers or blow bars to strike the flowing materials with a great force to break them apart. Horizontal shaft impactors can be useful as a primary or a secondary industrial crusher that can crush a variety of different materials, from very hard materials to soft rocks.

In operation, horizontal shaft impactors have a rotor that spins around the shaft (at a very high velocity). As the materials pass or flow into a chamber, the blow bars will strike the material repeatedly, which forces them to break apart. This sends the materials into hanging aprons, which results in the next step of reduction.

With the vertical shaft impactors, the orientation of the rotor is vertical, and rather than striking the materials with a great force, this system launches the material at a high speed where it is impacted by other rocks (around the perimeter of the rotor) or on the anvils. A vsi vertical shaft impactor is limited when it comes to the “feed size” they are able to process. They are also only used as a secondary or tertiary crusher.

In operation, the vertical shaft impactors involve feeding the material into a chamber above a spinning rotor. The material rapidly enters the moving wings of the rotor, where the materials are flung outwards where they break on rocks or peripheral anvils.

The final material size that is processed by the impact crusher is partly defined by the speed of the rotor. At a higher velocity, the materials are decreased to a much finer specification. At the same time, the closeness of the aprons to the actual rotor will also determine the size of the material. The output becomes finer and the aprons become closer.

The impact crushers are popular since they are useful for various types of material-processing applications and in various configurations, which makes them versatile stone crushers to invest in. From hard rock to soft rock, as either a secondary or primary crusher, impact crushers can also be custom-calibrated to make sure your venture is successful.