Construction waste is a growing problem in modern society, with vast amounts of debris and discarded materials piling up in landfills. The responsible disposal of construction waste is not only environmentally essential but also a regulatory requirement in many places. To address this issue, the use of stone crushers has become increasingly popular for effectively breaking down and recycling construction waste. However, with various types of stone crushers available in the market, choosing the right one can be a daunting task. In this article, we’ll explore the different types of stone crushers and help you determine which one is suitable for your construction waste disposal needs.

Primary Crushers

Primary stone crushers are the first step in the construction waste recycling process. These machines are responsible for reducing large and heavy materials to a manageable size. Jaw crushers and impact crushers are common choices for primary crushing.

Jaw Crushers

Jaw crushers, also known as compression crushers, use a fixed jaw and a moving jaw to crush construction waste. They are suitable for processing various types of materials, including concrete(trituradora de hormigóns), bricks, and asphalt. Jaw crushers are known for their efficiency in breaking down materials, making them an ideal choice for initial construction waste reduction.

Impact Crushers

Impact crushers, on the other hand, use a different mechanism to crush materials. They work by applying force to the construction waste, causing it to break along its natural lines of weakness. Impact crushers are versatile and can handle a wide range of materials, making them a suitable option for primary stone crushing in construction waste disposal.

Secondary Crushers

After the primary crushers have reduced the construction waste to a more manageable size, secondary stone crushers(trituradoras de piedra) come into play. These machines further reduce the material to a finer consistency. Common choices for secondary crushing include cone crushers and vertical shaft impact (VSI) crushers.

Cone Crushers

Cone crushers operate by compressing the construction waste between a stationary and a rotating mantle. They are excellent for creating fine aggregates and are often used for shaping and finalizing the recycled materials. Cone crushers are a suitable option when you need a finer, more uniform product from your stone crusher.

Vertical Shaft Impact (VSI) Crushers

VSI crushers are highly effective for shaping construction waste into a cubical, well-graded product. They work by accelerating the material and throwing it against a spinning rotor. VSI crushers are known for their ability to create high-quality, well-shaped aggregates, making them a suitable choice for secondary crushing in construction waste recycling.

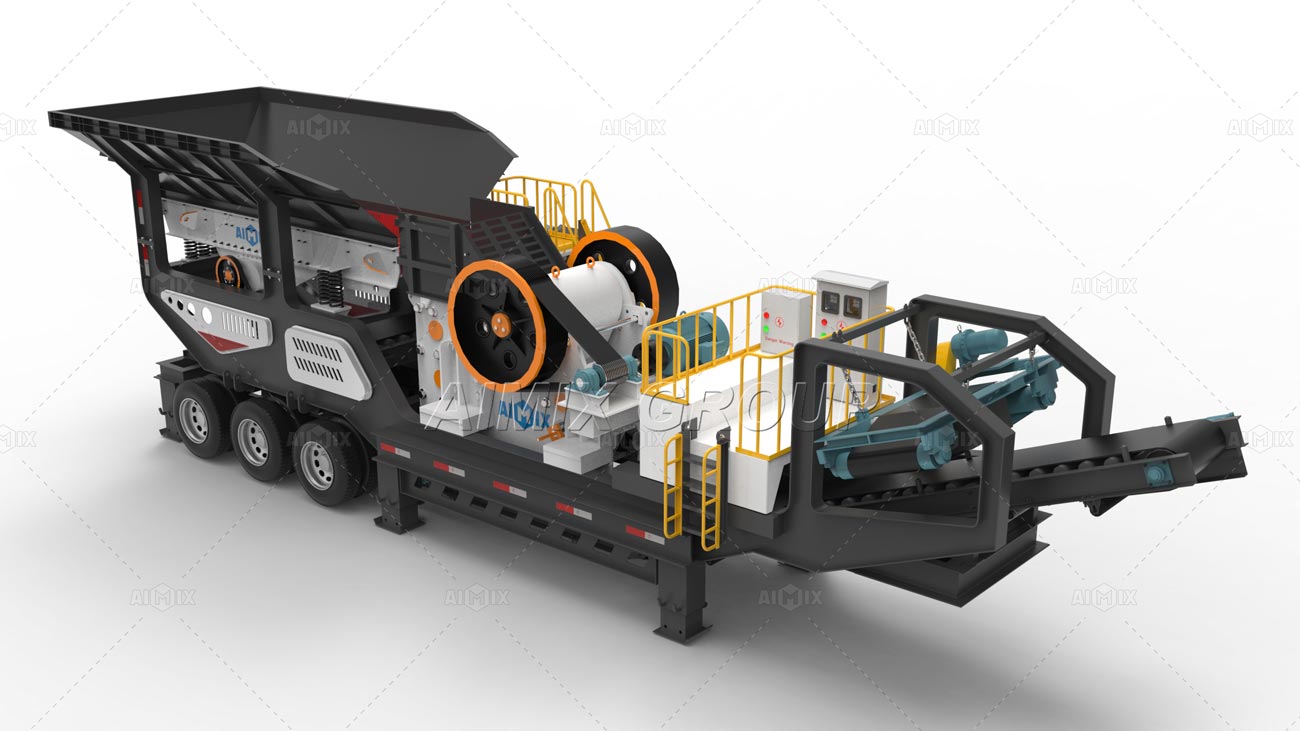

Mobile Crushers

Mobile stone crushers(Trituradoras de piedra móviles) are a convenient and versatile option for construction waste disposal. These crushers can be easily transported to different locations, allowing for on-site crushing of construction waste. They come in various types, such as mobile jaw crushers and mobile impact crushers, providing flexibility and efficiency in managing construction waste on the go.

Conclusion

In conclusion, choosing the right stone crusher for construction waste disposal depends on the specific requirements of your project. Consider the size and type of materials you need to process, as well as the desired end product. By understanding the various types of portable stone crushers(trituradora portátil de piedra) and their respective advantages, you can make an informed decision that will contribute to more efficient and sustainable construction waste management. Stone crushers play a crucial role in reducing the environmental impact of construction waste and turning it into valuable resources.